Impact characterization of Kevlar/Elastomer Composite Flat Panels

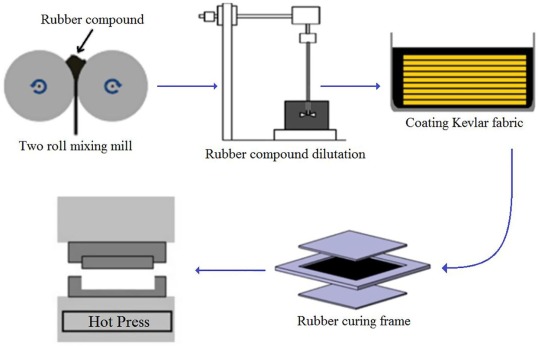

Light weight, high ballistic protection and flexibility are the most important characteristics of a personal armor. Ballistic fabrics based on high strength polymer fibers such as Kevlar are among the leading materials in ballistic impact field. On the other hand, rubber materials with ability to experience large deformation, along with features such as high energy dissipation, are good choices to use with ballistic fabrics as a Kevlar/rubber composite. This composite can work well under impact loading due to its flexibility and remarkable improvement in physical and mechanical properties. The main purpose of this research is to study the ballistic performance of Kevlar/rubber composite. Due to the high energy dissipation properties of rubber, it can be expected that the reinforcement of the Kevlar fibers with rubber, increase the energy absorption capacity of the composite under impact loads, significantly. In order to investigate this hypothesis, the ballistic performance of Kevlar/rubber composite has been investigated. This study has been conducted in two experimental and numerical sections that two approaches have been considered in numerical simulation of impact on composite. In the experimental section, the manufacturing of Kevlar/rubber composite and its mechanical properties and impact resistance of the specimens were investigated. The fabrication of the specimens was done by dipping the Kevlar fabric in the diluted rubber compound.

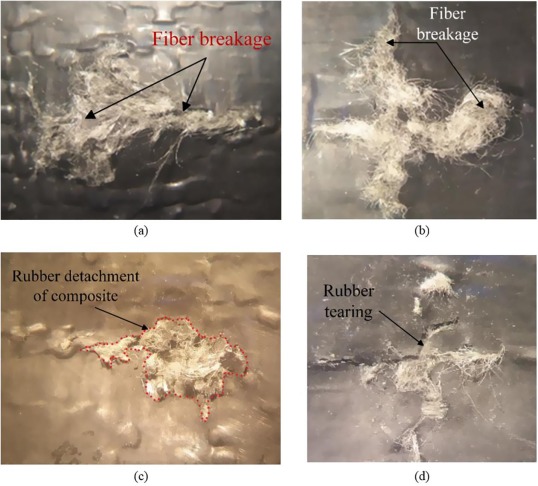

Two types of rubber with different components were used to fabricate the specimens to investigate the effect of rubber matrix with different hardness and properties on the ballistic performance of elastomeric composites. The ballistic test was performed to evaluate the impact resistance of the specimens. Moreover, ballistic tests were performed on neat Kevlar fabric and Kevlar/epoxy composite and their ballistic performance was compared with elastomeric composite performance. The results showed the positive effect of using rubber as a matrix on the ballistic performance of the composite. The ballistic limit of two- and four-layer Kevlar/rubber composite with high hardness rubber increased about 19 and 41% compared to the ballistic limit of two- and four-layer Kevlar fabrics, respectively. Also, the increase in ballistic limit for two- and four-layer Kevlar/rubber composites with low hardness was 9 and 21%, respectively, compared to the ballistic limit of two- and four-layer Kevlar fabrics.

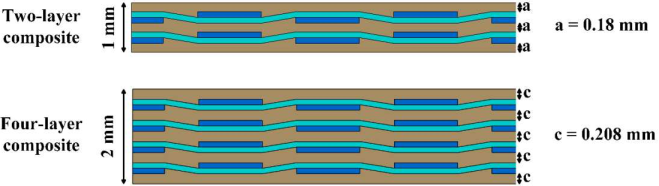

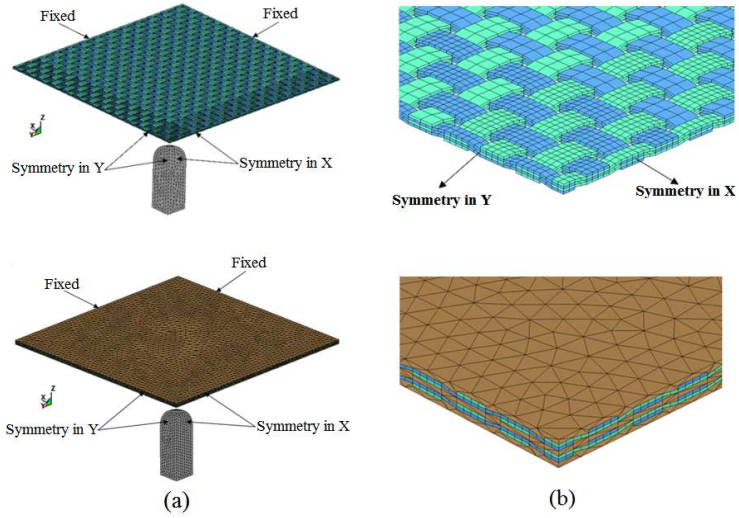

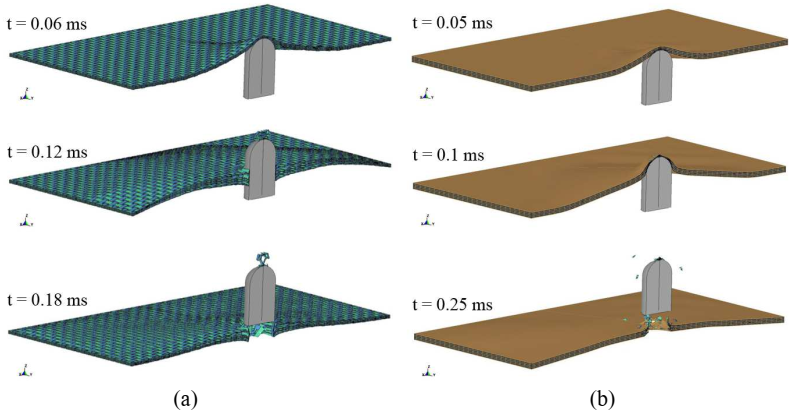

For numerical analysis of impact on elastomeric composites, simulation was performed based on two macroscopic and microscopic approaches. In the microscopic modelling, warp and weft fibers were modeled separately and weave together to form the fabric structure. By modeling the rubber matrix as a net between and around the warp and weft fibers, the Kevlar/rubber composite was modeled. The warp and weft properties were obtained by performing tensile test on a single yarn.

Also, due to the strain rate dependent properties of rubber, its properties were obtained by Split Hopkinson pressure bar device. By modeling the projectile and applying appropriate constraints between the fabric and the rubber matrix, the simulation of impact on the composite was analyzed using LS-DYNA finite element software. The results of all simulations include two- and four-layer fabric samples and Kevlar/rubber composites with low and high hardness, indicating acceptable agreement between experimental and numerical results.

Selected Journal Papers

- Khodadadi, Amin, Gholamhossein Liaghat, Ahmad Reza Bahramian, Hamed Ahmadi, Yavar Anani, Samaneh Asemani, and Omid Razmkhah. "High velocity impact behavior of Kevlar/rubber and Kevlar/epoxy composites: A comparative study." Composite Structures 216 (2019): 159-167.

- Khodadadi, A., Gh Liaghat, S. Vahid, A. R. Sabet, and H. Hadavinia. "Ballistic performance of Kevlar fabric impregnated with nanosilica/PEG shear thickening fluid." Composites Part B: Engineering 162 (2019): 643-652.

- Khodadadi, Amin, Gholamhossein Liaghat, Hamed Ahmadi, Ahmad Reza Bahramian, Yavar Anani, Omid Razmkhah, and Samaneh Asemeni. "Numerical and experimental study of impact on hyperelastic rubber panels." Iranian Polymer Journal 28, no. 2 (2019): 113-122.

- Khodadadi, Amin, Gholamhossein Liaghat, Hamed Ahmadi, Ahmad Reza Bahramian, and Omid Razmkhah. "Impact response of Kevlar/rubber composite." Composites Science and Technology 184 (2019): 107880.